Calibration Certificate Template

Calibration Certificate Template - Calibration is a process of giving a known input to the measurement system and taking necessary actions to see that the output of the measurement system matches with its input. Discover the critical role of calibration in industrial manufacturing. A meticulous process ensuring measurement accuracy. Learn how it mitigates risks, reduces costs, and ensures compliance. Calibration is the process of adjusting and comparing a measuring instrument with a known standard to ensure its accuracy. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. Calibration is key to ensuring accurate measurements and helping to improve efficiency, compliance, and safety, while minimizing emissions, waste, and risk. Understand the essence of calibration: The concept of calibration has become fundamental in most production and manufacturing environments, especially with digital devices. It helps to detect and correct errors in measurements,. Calibration is key to ensuring accurate measurements and helping to improve efficiency, compliance, and safety, while minimizing emissions, waste, and risk. Calibration is a process of giving a known input to the measurement system and taking necessary actions to see that the output of the measurement system matches with its input. A meticulous process ensuring measurement accuracy. It helps to detect and correct errors in measurements,. The concept of calibration has become fundamental in most production and manufacturing environments, especially with digital devices. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Calibration is the process of adjusting and comparing a measuring instrument with a known standard to ensure its accuracy. Companies need to improve and. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. Each step in the process is crucial for maintaining operational. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Calibration is the process of adjusting and comparing a measuring instrument with a known standard to ensure its accuracy. Each step in the process is crucial for maintaining operational. It helps to detect. Discover the critical role of calibration in industrial manufacturing. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Each step in the process is crucial for maintaining operational. It helps to detect and correct errors in measurements,. Learn how it mitigates risks,. Discover the critical role of calibration in industrial manufacturing. It helps to detect and correct errors in measurements,. Learn how it mitigates risks, reduces costs, and ensures compliance. The concept of calibration has become fundamental in most production and manufacturing environments, especially with digital devices. Calibration is a process of giving a known input to the measurement system and taking. Calibration is a structured process designed to ensure measurement devices perform accurately and reliably. Calibration is key to ensuring accurate measurements and helping to improve efficiency, compliance, and safety, while minimizing emissions, waste, and risk. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Understand the essence of calibration: Calibration is a process of giving a known input to the measurement system and taking necessary actions to see that the output of the measurement system matches with. A meticulous process ensuring measurement accuracy. Calibration is the process of adjusting and comparing a measuring instrument with a known standard to ensure its accuracy. Understand the essence of calibration: Calibration is a process of giving a known input to the measurement system and taking necessary actions to see that the output of the measurement system matches with its input.. Calibration is the process of adjusting and comparing a measuring instrument with a known standard to ensure its accuracy. Calibration is a process of giving a known input to the measurement system and taking necessary actions to see that the output of the measurement system matches with its input. Calibration is a structured process designed to ensure measurement devices perform. It helps to detect and correct errors in measurements,. A meticulous process ensuring measurement accuracy. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Discover the critical role of calibration in industrial manufacturing. Learn how it mitigates risks, reduces costs, and ensures. It helps to detect and correct errors in measurements,. Discover the critical role of calibration in industrial manufacturing. A meticulous process ensuring measurement accuracy. Each step in the process is crucial for maintaining operational. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that. The concept of calibration has become fundamental in most production and manufacturing environments, especially with digital devices. A meticulous process ensuring measurement accuracy. Discover the critical role of calibration in industrial manufacturing. Understand the essence of calibration: Calibration is key to ensuring accurate measurements and helping to improve efficiency, compliance, and safety, while minimizing emissions, waste, and risk. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. Calibration is the process of adjusting and comparing a measuring instrument with a known standard to ensure its accuracy. Companies need to improve and. A meticulous process ensuring measurement accuracy. Understand the essence of calibration: In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Learn how it mitigates risks, reduces costs, and ensures compliance. Calibration is a structured process designed to ensure measurement devices perform accurately and reliably. Each step in the process is crucial for maintaining operational. It helps to detect and correct errors in measurements,. Calibration is key to ensuring accurate measurements and helping to improve efficiency, compliance, and safety, while minimizing emissions, waste, and risk.Instrument Calibration Questions and Answers

Verify or calibrate measuring instruments? WIKA blog

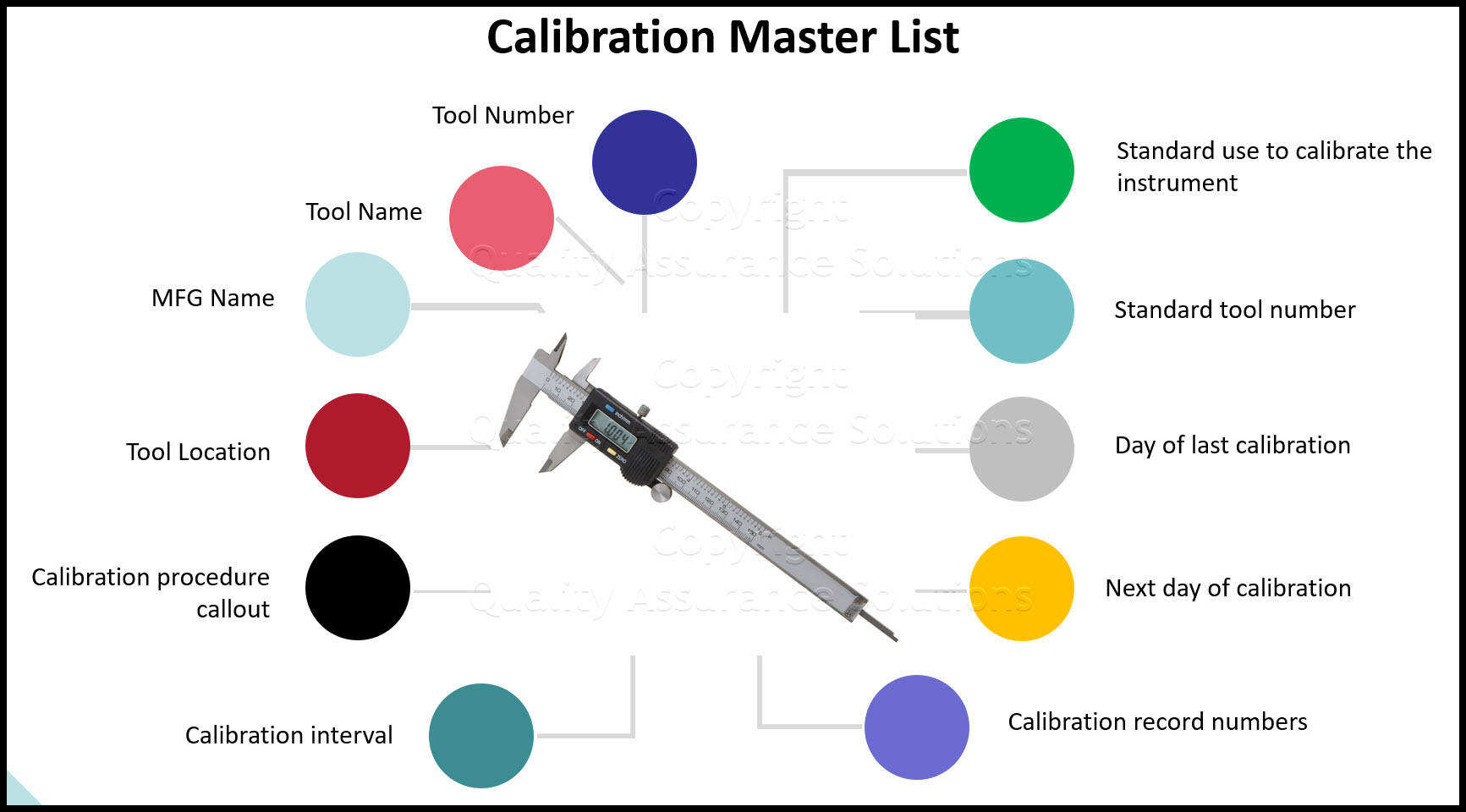

CALIBRATION

What Is Instrument Calibration and Why Is it Needed? Technical Articles

BSN Diklat Detail Pelatihan

12,100+ Calibration Stock Photos, Pictures & RoyaltyFree Images iStock

Comprehensive Guide on Calibration Software

What Is Instrument Calibration and Why Is it Needed? Technical Articles

National Calibration Standards at henryeschrantzo blog

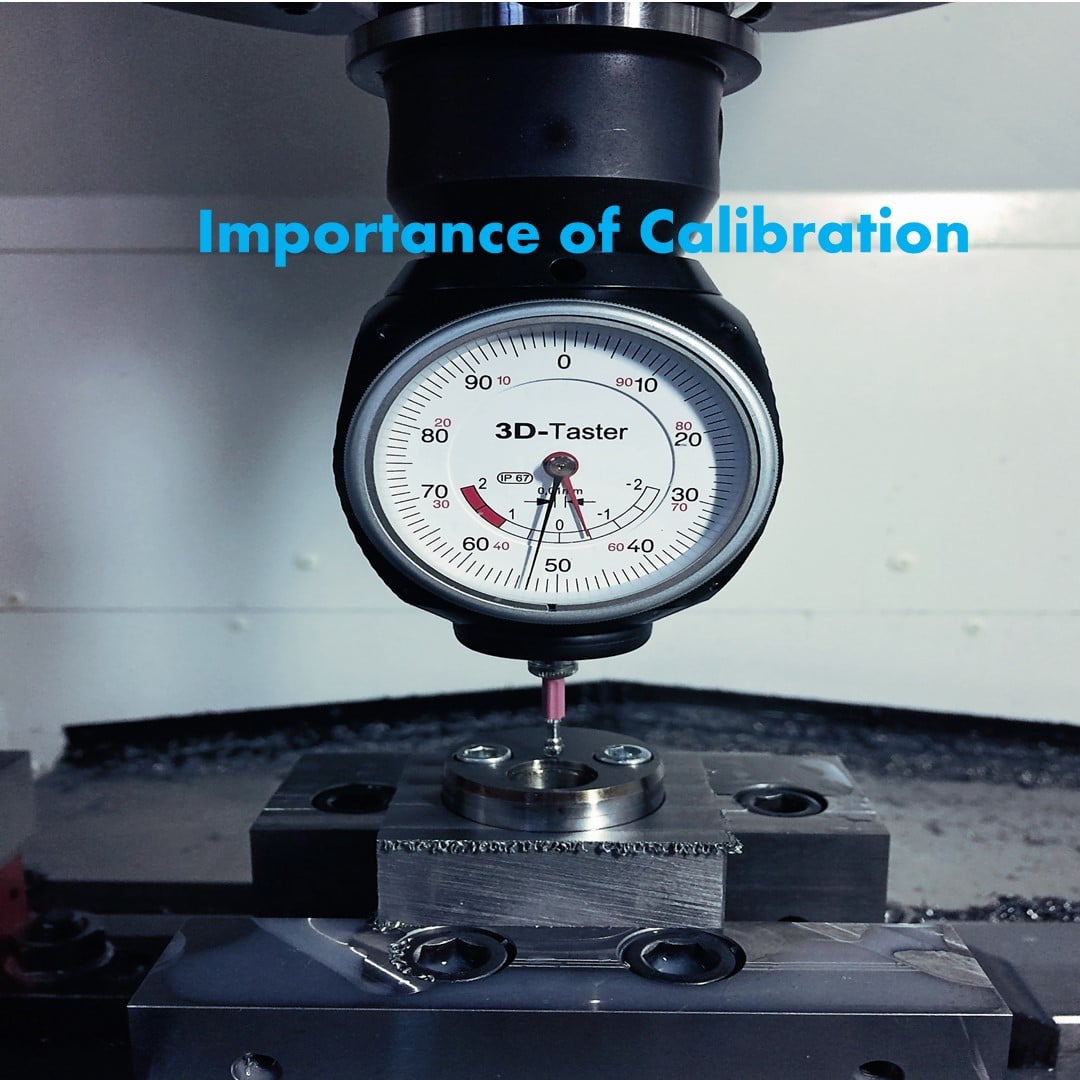

Important Calibration Is Essential And It Impacts Accuracy

The Concept Of Calibration Has Become Fundamental In Most Production And Manufacturing Environments, Especially With Digital Devices.

Discover The Critical Role Of Calibration In Industrial Manufacturing.

Calibration Is A Process Of Giving A Known Input To The Measurement System And Taking Necessary Actions To See That The Output Of The Measurement System Matches With Its Input.

Related Post: